HOW TO APPLYING HIGH TEMPERATURE GREASE FOR BEARINGS DRUM.

After a period of use in a coffee roasting drum, it is inevitable that the bearings of the roasting drum will become dry and greased. In particular, the unique nature of the roasting drum is always exposed to high temperatures, along with the mechanism of continuous rotation during operation, causing the bearings to friction and heat up. This affects the rotation speed of the roasting drum, causing wear and tear, causing the machine to quickly fail.

It is known that bearings are consumable devices during use. But how to prolong their lifespan, today Mars would like to share briefly in the hope that people using coffee roasters will have more useful information to help their roasters operate smoothly. the safest and most effective way.

The fastest and most effective solution to overcome the condition of bearings drying out, wearing out, quickly damaging… is to regularly apply high grease to them.

So what is lubricating grease for bearings and heat-resistant bearings?

Heat-resistant grease is a type of grease that when applied to bearings and housings can operate at high speeds and temperatures. It is a technical term for greases for bearings that are capable of operating accurately even when reaching extremely high revolutions per minute (RPM) and generating heat.

How to choose grease to lubricate the bearings and bearings of the coffee roasting drum:

Currently, the market sells many types of heat-resistant lubricants. If we are not clear, we will buy products that do not suit our needs and purposes. We should choose heat-resistant greases that can withstand heat at least: 200°C with thickeners that do not have a dripping temperature, are able to withstand acids, have a small friction coefficient, are rust and rust resistant abrasive.

Procedure for applying heat-resistant grease to bearings and drum supports:

Step 1: Open the screws attached to the stainless steel surface and the front bearing of the drum.

Step 2: After disassembling the front stainless steel surface, we will see the bearings inside.

Step 3: Apply a sufficient amount of heat-resistant grease around the bearing.

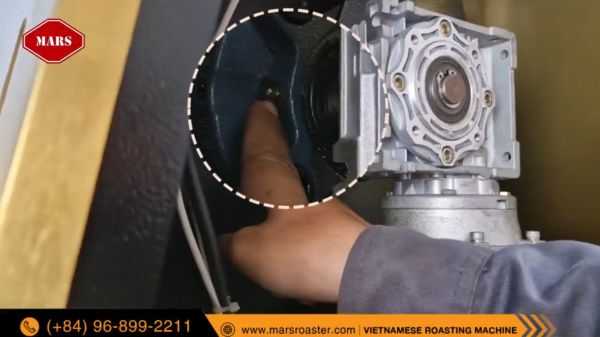

Step 4: After completing the front bearing, we continue to apply heat-resistant grease to the roasting drum support located at the back of the roaster. Remember to remove the cooling fan mounted on the back of the machine.

Step 5: Use a grease gun to pump grease into the mouth of the bearing (grease pump) a sufficient amount, not too much nor too little. The amount of heat-resistant grease injected will depend on the capacity of the coffee roaster, whether the bearings and bearings installed are large or small.

Step 6: Check after completing the lubrication of the bearing and bearing by starting the machine to see if the amount of grease you put in is too much or too little.

If it’s too little, when the engine operates, it will create a rattling sound and friction sound… but if it’s too much, the amount of grease will be excess and spill out… checking again will help you promptly fix it, and at the same time make sure. Once again, your roaster is working fine.

So how often should you apply heat-resistant grease to bearings ?

Applying the formula to calculate lubrication frequency based on the bearing size you are using will be very difficult and troublesome for machine users.

Therefore, Mars, with experience as a manufacturer, would like to share in the most abstract and easy-to-understand way for customers to clearly understand the process and cycle of pumping heat-resistant grease for their machines: If your roaster must operate Continuous operation for 8 hours/day, then after 2 weeks you should grease once. And vice versa, if your roaster can roast more or less, you can grease after 1 week to 1 month…

To learn more about the process of applying heat-resistant grease to bearings and housings. Customers can watch the instructional video below: